Ocean Engineers have a wide range of employment opportunities world - wide. Because of the wide variety of work they are involved in and the difficulty to categorise the field comprehensively, the Ocean Engineers are mainly related to engineering field as designers and construction supervisors, they also have scope in areas like Consultancy, Marketing and Sales, Operations, Regulation, Surveying and Overseeing, Research and Development, Education and Training, etc.

Each type of work has its own distinctive character and offers opportunities for initiative and imagination in a wide variety of technical and managerial posts.

The work place may be a large company, a small group, a consultancy or a government department, but their scopes are wide.

As a Coastal Engineer, they are dealing with the dynamic interaction of ocean and its shore by developing shore protection systems like breakwaters, jetties, etc., and designing harbours, ports, etc., and also dealing with civil engineering issues in the coastal environment.

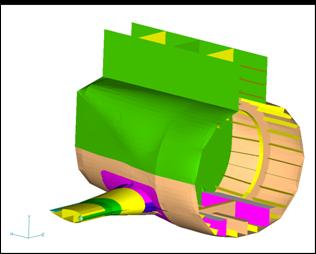

As Offshore Engineers, they design structures like steel jacket structures, concrete gravity platforms, tension - leg platforms, etc., which are capable of withstanding the severe ocean environment.

As an Environmental Engineer, they have to protect the oceans from the harmful effects of mankind's activities. They are involved in harvesting and / or utilizing the oceanic resources such as minerals, wave energy, thermal energy and tidal power.

Depending mainly on the type of Qualifications held and personal inclination, Ocean Engineers may become specialists in one field or develop broad experience in others.

Eventually they may find themselves in senior executive positions using their knowledge and experience of general management as well as their professional skills in engineering and project leadership.

Indeed, aided by the breadth of their education, training and experience, the professional Naval Architects and Ocean Engineers are even successful in top management positions in government, industry and commerce quite outside the offshore field.

Main Areas of Scope :

There are lots of opportunities For Ocean Engineers and Naval Architects in the private, educational, corporate, and governmental sectors.

Some career areas to consider are : Offshore Oil Recovery, Marine metals and corrosion, Environmental Protection, Global Climate Monitoring, Renewable Energy, Underwater Vehicles, Remote Sensing, Marine Transportation, or Naval Architecture and Defence. Therefore, some main areas of scope are as follows :

Design Office :

Ocean Engineers are by necessity innovative and creative personalities. They must have an understanding of the many facets of offshore structure design such as its function, appearance and especially importance at sea safety.

They must be team leaders, able to integrate the inputs of many others to achieve a balanced and coherent whole. As a Naval Architect, apart from the architectural aspects of ship form and layout, they must be able to use complex mathematical and physical models to ensure that the design is satisfactory technically and that it meets the safety rules and standards laid down by Classification Societies and Government Agencies.

Since, the design process demands the extensive employment of computer based information and communication systems. Ocean Engineers should also be well versed in computer software knowledge.

As a design office employee, they are employed by ship and boat builders, offshore constructors, design consultants, and for the ships and submarines of the Navy and the Ministry of Defence.

Major equipment manufacturers also employ teams of engineers, including Naval Architects and Ocean Engineers on the design of such products as propulsion systems, auxiliary systems sub sea production systems and control systems.

Field Engineer :

The task of the ship and boat builders and offshore constructor is to convert drawings and detailed specifications into real structures. A Naval Architect and Ocean Engineers specialising,, in. construction usually holds a management post, taking responsibility for the management of the whole yard / site or for sections of it such as planning, production or the complex operation of fitting out.

There should continuously strive to make construction work efficient through the adoption of new processes and practices and by better training for the work force. The Ocean Engineers must also organise the supply of materials and components, inspection and testing as well as the vital resources of manpower.

Repair work has much in common with construction. Ocean Engineers and Naval Architects in this field can become professional managers in future, who like the builders need to master modern management and associated techniques.

Emergency repair work often offers opportunities for ingenuity and on - the - spot improvisation, and in the offshore engineering world in particular repair frequently involves underwater technology.

Therefore, as a site engineer, they are employed in construction and repair include both large and small shipbuilders and repairers, and those involved in the maintenance and repair of naval ships, submarines, harbours, ports and other offshore structures.

Consultant :

As consultants, Ocean Engineers and Naval Architects provide clients with engineering solutions, technical and commercial guidance and project management for concept design studies, new offshore structure developments, new vessel constructions, refits and conversions.

Therefore, they are employed to give professional advice and technical support to customers of the offshore industry.

Ship Surveyor :

Naval Architects and Ocean Engineers employed by Classification Societies as Ship Surveyors are engaged world - wide in evaluating the safety of ships and marine structures using the Society's Rules and those of intergovernmental organisations such as the International Maritime Organisation.

Plans of ships to be built and eventually classed with the Society are scrutinised, and aspects of design such as strength, stability, and lifesaving approved before construction.

Also during construction, Ship Surveyors carry out inspections to ensure that the quality of the workmanship and materials used is in accordance with the rules and regulations.

Once the vessel or structure is in service, Ship Surveyors will continue to carry out inspections to ensure that any serious defects arising from operation are made good and that a safe and seaworthy structure is maintained.

Government departments employ Naval architects who deal mainly with the framing of safety regulations and the surveying of ships and equipment from the safety point of view.

Research and Development :

Offshore research, in general, enjoys a high reputation world - wide. The Naval Architects and Ocean Engineers, many with post - graduate qualifications, are engaged in research in universities and industry throughout the world.

Classification Societies also devote resources to research and development employing Naval Architects in this field.

This variety of work provides a rewarding challenge to the Ocean Engineers and Naval Architects, not only as engineers but also as managers, consultants, surveyors, scientists, etc.

Institutes offering the Naval Architecture and Ocean Engineering Courses :

The various institutes in India providing Bachelor and Master degree in Ocean Engineering and Naval Architecture are as follows :

| S. No. | Institutes | Offered Courses |

|---|

| 1 | Indian Institute of Technology Madras, Chennai - 600 036. | Ocean Engineering and Naval Architecture |

| 2 | Indian Institute of Technology Kharagpur, Kharagpur - 721 302. | B.Tech - Ocean Engineering and Naval Architecture M.Tech - Ocean Engineering and Naval Architecture |

| 3 | National Institute of Technology Surathkal, Mangalore - 575025. | M. Tech in Marine Structures |

| 4 | National Institute of Technology Calicut, Calicut - 673 601. | M. Tech in Offshore Structures |

| 5 | Cochin University of Science and Technology, Cochin. | M.Tech in Ocean Technology |

| 6 | Chennai School of Ship Management, Mambakkam, Chennai - 600 048. | Diploma Program in Marine Engineering |

| 7 | College of Engineering (Autonomous), Andhra University, Visakhapatnam - 530 003. | B.E. Naval Architecture, M.E. Hydraulic, Coastal & Harbour Engineering |

| 8 | Institute of Shipbuilding Technology, Vasco da Gama, Goa - 403 802. | 4 Year diploma Program in Shipbuilding Engineering |

It is a new field and is making tremendous advancements. It is our only frontier - we know less about the oceans than we do about the moon - so it is new and extremely rewarding. There is so much we have yet to learn about our oceans. Therefore, it is for sure that the career opportunities in this field will absolutely increase further.

There are not enough ocean scientists or engineers to meet all the demands of the day. Also, tomorrow's greatest discoveries in science, medicine and life knowledge will come from the oceans.

Demand drivers: Being a global industry, the fortunes of the shipbuilding industry are closely tied to the growth in world trade. The demand for ships can be classified into incremental demand and replacement demand. In case of incremental demand, growth in world trade increases the demand for vessels, which in turn leads to higher freight rates. The resultant higher freight rates trigger the demand for new vessels from the shipping companies. In case of replacement demand, the demand for vessels is dependent upon the age profile of the existing fleet as well as steel prices. Every ship has a useful life (25 to 30 years) after which it becomes uneconomical to operate them. Replacement demand is triggered when ships approach the end of their useful life. Higher steel prices also decide the extent of replacement demand as they lead to an increase in value of ships to be scrapped.

Demand drivers: Being a global industry, the fortunes of the shipbuilding industry are closely tied to the growth in world trade. The demand for ships can be classified into incremental demand and replacement demand. In case of incremental demand, growth in world trade increases the demand for vessels, which in turn leads to higher freight rates. The resultant higher freight rates trigger the demand for new vessels from the shipping companies. In case of replacement demand, the demand for vessels is dependent upon the age profile of the existing fleet as well as steel prices. Every ship has a useful life (25 to 30 years) after which it becomes uneconomical to operate them. Replacement demand is triggered when ships approach the end of their useful life. Higher steel prices also decide the extent of replacement demand as they lead to an increase in value of ships to be scrapped.  Major players in the shipbuilding countries: Global market environment in the shipping industry has undergone fundamental changes over the last two decades. For nearly three decades in the post World War II era, shipbuilding industry was dominated by Europe and the US. Shipbuilding being a labour intensive industry, the cost of labour plays an important determinant in a country’s competitiveness position vis-à-vis others. With rising labour cost, shipbuilding activities have slowly moved away from ‘high wage’ Europe and US to low-wage Asia. Over the past 25 years, we have observed the decline of shipbuilding capacity in Europe coinciding with the growth of Japanese shipbuilding. As can be seen in the chart, the share of European Union has declined from 28% in 1983 to 7% in 2005. With the rising labour cost in the late 1980s, Japan was forced to scale down its shipbuilding activities and Korea emerged aggressively. In the past few years, China is taking away an increasingly larger market share of the new building contracts.

Major players in the shipbuilding countries: Global market environment in the shipping industry has undergone fundamental changes over the last two decades. For nearly three decades in the post World War II era, shipbuilding industry was dominated by Europe and the US. Shipbuilding being a labour intensive industry, the cost of labour plays an important determinant in a country’s competitiveness position vis-à-vis others. With rising labour cost, shipbuilding activities have slowly moved away from ‘high wage’ Europe and US to low-wage Asia. Over the past 25 years, we have observed the decline of shipbuilding capacity in Europe coinciding with the growth of Japanese shipbuilding. As can be seen in the chart, the share of European Union has declined from 28% in 1983 to 7% in 2005. With the rising labour cost in the late 1980s, Japan was forced to scale down its shipbuilding activities and Korea emerged aggressively. In the past few years, China is taking away an increasingly larger market share of the new building contracts.