Chronic Cracking in an Aluminum SWATH Research Vessel

Vessel Particulars

LOA: 117’-3 5/8”

Breadth: 53’-0”

Depth: 25’-0”

Draft: 12’-0”

Gross Tonnage: 499

Displacement: 419 LT

Complement: 26 (10 crew, 16 science)

Maximum Speed: 14.5 knots

Endurance: 4000 NM at 8 knots

Builder: SWATH Ocean Systems

Year Built: 1996

ID No.: 1038571

Class: None, COI and Load Line

Flag: US

Owner/ Operator: Monterey Bay Aquarium Research Institute, Moss Landing, CA

Vessel Type: SWATH (Small Waterplane Area Twin Hull), Diesel Electric Propulsion

Hull Material: Aluminum

Figure 1. Profile of R/V WESTERN FLYER

Summary of Structural Failure

R/V Western Flyer has experienced localized cracking to its aluminum structure during typical operations during virtually all of its twelve year life span. Various modifications have been implemented in an attempt to solve this problem.

Background

Design

R/V Western Flyer was designed and built by SWATH Ocean Systems in 1996 for Monterey Bay Aquarium Research Institute (MBARI). The design was based on successful SWATH Ocean Systems designs for smaller vessels. Although USCG was involved in the review of the design, extensive detailed structural analysis was not completed in the design phase.

R/V Western Flyer’s mission is to provide a stable platform for ROV operations for MBARI’s Tiburon in water up to 4000m. Because of the extreme water depth and the rapid changes in weather encountered in the Monterey Basin area, it is necessary for the R/V Western Flyer to be able to operate up to Sea State 5. In order to facilitate ROV deployment and retrieval, especially in higher sea states, an internal moon pool is utilized.

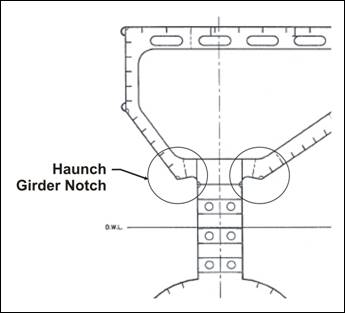

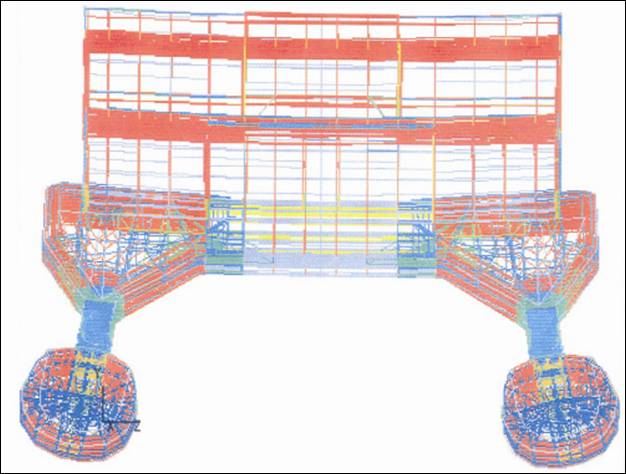

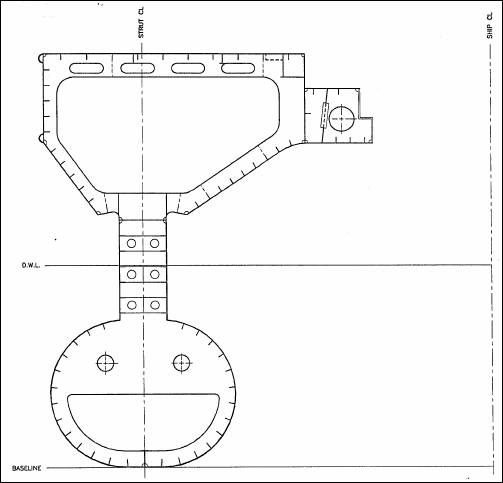

Figure 2 shows a typical transverse web frame. All structure is 5086 aluminum, except for isolated bulkhead and deckhouse framing that is 6061. Web frames are spaced every three feet, with transverse bulkheads every 15 feet.

Figure 2. Transverse Web Frame

Events leading to failure

During one of R/V Western Flyer’s early voyages, the bilge alarm in the steering flat was activated. The crew discovered water seeping through cracks in the transom. Further investigation located cracking in several other locations throughout the vessel. Weather conditions had been moderate (Sea State 3-4) from the starboard beam.

Detailed Description of Structural Failure

While the cracking in the transom was the result of coincident plate seams, butts and corners, the majority of the cracking was in transverse frames and watertight bulkheads in way of the haunch girder notch. Cracking in the transverse frames was primarily in locations without adequate bracketing in way of the notch. Some side shell cracking was seen in way of the transverse bulkheads. See Figure 3.

Figure 3. Haunch Girder Notch

Initial Analysis and Repair

In order to continue operating while extensive structural analysis was performed, the strategy of repair and monitoring was adopted. All cracks were repaired and brackets were installed on those frames without them previously. In order to assess the efficacy of the repair, operation was to proceed in worsening sea conditions with the possibility of altering course to minimize loading on the structure.

In the first two months of limited operation and vessel monitoring, over 100 new cracks developed. All of these cracks were at the ends of welds in the haunch area. A stress monitoring program was installed on the vessel to provide a visual and audible alarm on the bridge to alert the crew of a need to change course.

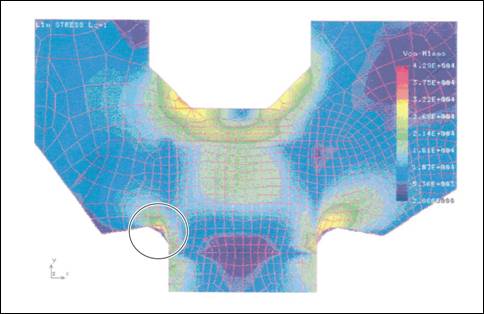

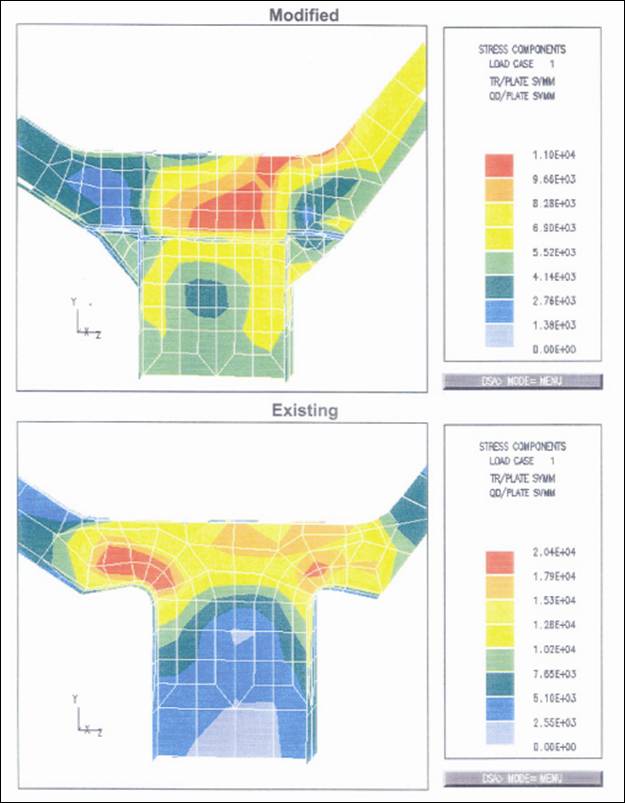

Two-dimensional finite element analysis was completed on a typical bulkhead and web frame. Loading on the models was determined based on beam seas in Sea States 3-5. The loading on the hull for a regular incident wave over a range of frequencies was calculated using MIT’s wave analysis program (WAMIT). The response in regular waves was applied to a Bretschneider spectrum to determine the extreme loads for each mode (roll, heave, pitch, etc.). Because the extreme forces do not occur together, combinations were created maximizing one mode at a time. The results of this initial FEA showed that even with brackets in place the stress in the haunch girder notch was over 40,000psi in Sea State 5. See Figure 4.

Figure 4. Stress in Transverse Bulkhead, Beam Sea, Sea State 5

Detailed Analysis

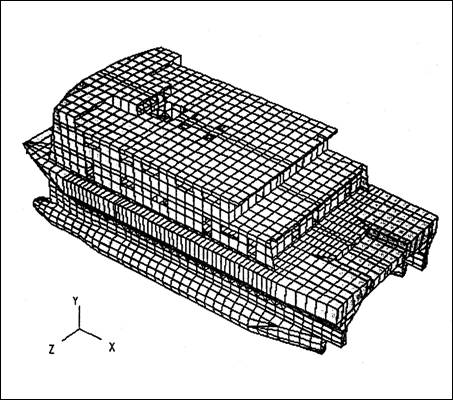

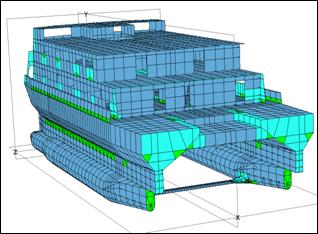

In order to understand more fully the response of the structure of the R/V Western Flyer, a global three dimensional finite element model of the entire hull and deckhouse was constructed. See Figure 5.

![]()

Figure 5. Global 3-D Finite Element Model

A pressure distribution over the wetted surface of the hull was developed using an equivalent irregular wave. The resulting loading is a squeezing/prying moment acting on the pontoons. This analysis was repeated for the vessel with the proposed modifications to assess their effectiveness. The design load for the modified vessel is higher than the existing due to changes in the pontoons to counteract weight addition.

Figure 6. Deflection Plot, Prying Condition

Results of the global FEA confirmed failures experienced in several areas of the vessel. High stresses were shown in the haunch girder notch areas and at the corners of the deckhouse bulkhead and deck intersections. Panel buckling was calculated (and had occurred) in the transverse structure aft of the moonpool and in areas of the deckhouse.

Modification

The following modifications were accomplished at Bay Ship and Yacht in Alameda, CA between 1998 and 1999.

- Faired the notch between the strut and haunch.

- Added half frames in way of the haunch.

- Deepened existing haunch frames.

- Added half frames aft of the moonpool.

- Increased stiffening in the deckhouse.

- Replaced aft bulkhead of house with thicker plate of stronger aluminum.

- Increased diameter of pontoons over a portion of their length to compensate for additional weight.

Figure 7 shows the effect of the modification to the haunch girder notch on the stress distribution.

Figure 7. Haunch/Strut Stress with/without Fairing

End Result

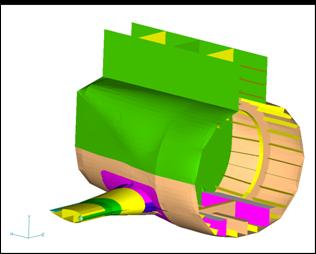

Unfortunately, the 1998 modifications were not sufficient to completely solve the cracking problem on R/V Western Flyer. She continued to experience cracking at the junction of the deckhouse and main deck. Because the deckhouse is stepped away from the side, the prying moment causes the deck to bend up around the house. In 2005, after various other attempts, a strut was added aft at Frame 28 to connect the hulls to resist prying. See Figures 8 and 9. Frame 28 was chosen because it coincides with transverse bulkheads above and below deck, specifically the aft house bulkhead. Because ROV operations are conducted through a moon pool, strut installation any further forward would interfere.

The crew reports no adverse effects on performance due to either the aft strut or the increase in pontoon diameter. Continued crack monitoring shows no additional cracking in way of the haunch or pontoon joints.

Figure 8. Global Model with Strut Installed

Figure 9. Pontoon Strut

Design Observation

In retrospect, there are certain features of the design of R/V Western Flyer that could have been improved in earlier phases. The first is the concave bracketing in way of the haunch joint. In theory this was done to reduce spray. The second is to have the deckhouse side inset from the hull side, especially without, adequate structural members below to help distribute the load where the house side crosses the below deck bulkhead.

While earlier incorporation of the pontoon strut might have obviated some structural modifications, it was ruled out in the initial design due to the interference with ROV operations through the moon pool. It is not likely that the strut alone would have eliminated all cracking problems, particularly in way of the haunch.

Acknowledgements

References:

[1] Dockter, M.E. and K. Schmidt, “SWATH Research Vessel: The Building of RV Western Flyer,” Marine Technology, July 1996.

[2] Van Slyke, Morgan, Leach and Etchemendy, “R/V Western Flyer – Hull Strength Upgrade,” SNAME Pacific Northwest Section, 17 April 1999.

1 comment:

ship managers in chennai

Our crew management services include recruitment, selection, training, and management of officers and cadets and rating them for suitability and deployment for different vessels.

Post a Comment